Tsanangudzo

Face Milling Cutter For Aluminium Ingot

Product Overview:

Iyo aluminium ingot face milling cutter yakagadzirirwa kugaya kwepamusoro kusati kwapisa

process of aluminium ingots.The aluminium material face milling cutter series inosanganisira rough

Zvigayo zvinocheka, zvigayo zvakarurama, uye zvigayo zvakavharwa

inoshandiswa pakugaya zvakawanda zvema rough blanks.Iyo chaiyo milling cutter inoshandiswa kuvandudza

pamusoro kutsetseka kwealuminium ingots.Iyo yakavharwa milling cutter inosimudzira kusapfeka uye hupenyu hwema blades.

Product Features:

1, Mupendero wekugaya wakapinza, uchiita kuti pave nenzvimbo yakatsetseka pane yakagayiwa aluminium ingot, ine yakanaka.

kugadzirisa kugadzikana.

2, Iyo blade ine yakakwira density uye kugadzikana, ichipa yakanakisa kukanganisa kupikisa uye kupfeka kuramba. 3, Iyo blade yepamusoro ine kutsvedzerera kwakanaka, kuve nechokwadi chekusanamatira uye kusapisa maitiro ekugaya.

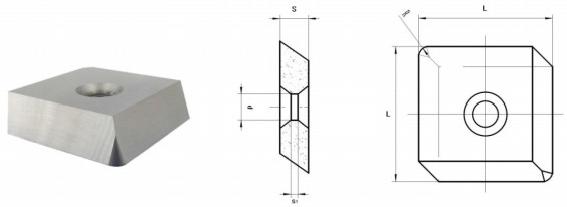

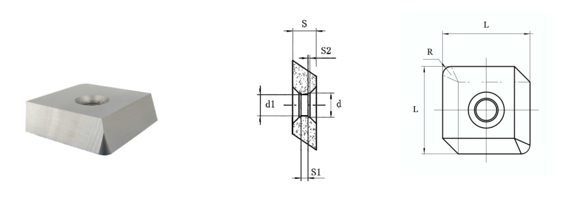

Rough Milling Cutter:

| Order Code | Dimension(mm | ||||

| L | R | d | S | s1 | |

| JT6206-L | 37.4 | 3 | 7 | 8 | 2 |

| Order Code | Dimension(mm) | ||||||

| L | R | S | S1 | S2 | d | d1 | |

| JT6206-M | 30 | 3 | 8 | 2.4 | 0.65 | 8.2 | 7.2 |

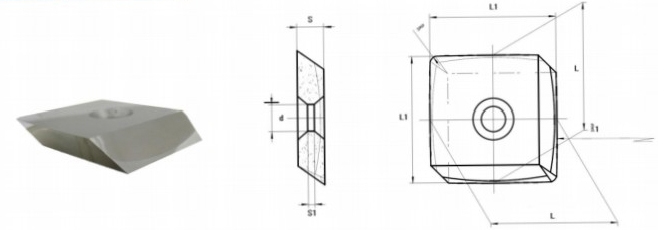

Pedzisa Milling Cutter:

| Order Code | Dimension(mm) | ||||||

| L | L1 | R | R1 | S | S1 | d | |

| JT6027 | 37.4 | 37.08 | 3 | 730 | 8 | 2 | 7.4 |

Coated Milling Cutter:

Grade List

| Giredhi | ISO Code | Zvenyama Mechanical Properties (≥) | Application | ||

| Density g/cm3 | Kuoma (HRA) | TRS N/mm2 | |||

| YG3X | K05 | 15.0-15.4 | ≥91.5 | ≥1180 | Inokodzera kunyatso kugadzirwa kwesimbi yakakandwa uye isina-ferrous simbi. |

| YG3 | K05 | 15.0-15.4 | ≥90.5 | ≥1180 | |

| YG6X | K10 | 14.8-15.1 | ≥91 | ≥1420 | Inokodzera kunyatso gadzira uye semi-kupedzisa kwesimbi yakakandwa uye isina-ferrous simbi, pamwe nekugadzirisa manganese simbi nesimbi yakadzima. |

| YG6A | K10 | 14.7-15.1 | ≥91.5 | ≥1370 | |

| YG6 | K20 | 14.7-15.1 | ≥89.5 | ≥1520 | Inokodzera semi-yekupedzisira uye yakakasharara machining eakakanda simbi uye akareruka alloys, uye anogona zvakare kushandiswa rough machining esimbi yakakandwa uye yakaderera alloy simbi. |

| YG8N | K20 | 14.5-14.9 | ≥89.5 | ≥1500 | |

| YG8 | K20 | 14.6-14.9 | ≥89 | ≥1670 | |

| YG8C | K30 | 14.5-14.9 | ≥88 | ≥1710 | Inokodzera inlaying rotary impact kucheresa dombo uye rotary impact yekuchera matombo. |

| YG11C | K40 | 14.0-14.4 | ≥86.5 | ≥2060 | Inokodzera kupinza chisel-shaped kana conical mazino mabhiti eanorema-basa kudhirowa dombo michina kubata yakaoma dombo maumbirwo. |

| YG15 | K30 | 13.9-14.2 | ≥86.5 | ≥2020 | Inokodzera kuyedzwa kwekumanikidza kwesimbi simbi uye pombi dzesimbi pasi pepamusoro compression ratios. |

| YG20 | K30 | 13.4-13.8 | ≥85 | ≥2450 | Inokodzera kugadzira stamping inofa. |

| YG20C | K40 | 13.4-13.8 | ≥82 | ≥2260 | Inokodzera kugadzira kutonhora kutsika uye kutonhora kudzvanya kunofira maindasitiri akadai seakajairwa zvikamu, mabhengi, maturusi, nezvimwe. |

| YW1 | M10 | 12.7-13.5 | ≥91.5 | ≥1180 | Inokodzera kurongeka machining uye semi-kupedzisa kwesimbi isina tsvina uye general alloy simbi. |

| YW2 | M20 | 12.5-13.2 | ≥90.5 | ≥1350 | Inokodzera semi-kupedzisa kwesimbi isina tsvina uye yakaderera alloy simbi. |

| YS8 | M05 | 13.9-14.2 | ≥92.5 | ≥1620 | Inokodzera kunyatso kugadzirwa kwesimbi-based, nickel-based high-temperature alloys, uye yakakwirira-simba simbi. |

| YT5 | P30 | 12.5-13.2 | ≥89.5 | ≥1430 | Inokodzera kurema-basa rekucheka kwesimbi uye simbi yakakandwa. |

| YT15 | P10 | 11.1-11.6 | ≥91 | ≥1180 | Inokodzera kurongeka machining uye semi-kupedzisa kwesimbi uye simbi yakakandwa. |

| YT14 | P20 | 11.2-11.8 | ≥90.5 | ≥1270 | Inokodzera kunyatso gadzira uye semi-kupedzisa kwesimbi uye simbi yakakandwa, ine mwero wekudyisa mwero. YS25 yakanyatsogadzirirwa kugaya mashandiro pasimbi uye simbi yakakandwa. |

| YC45 | P40/P50 | 12.5-12.9 | ≥90 | ≥2000 | Inokodzera zvinorema-basa rekucheka maturusi, zvichipa zvakanakisa mhedzisiro mukuchinjika kwakakasharara kwekukanda uye akasiyana simbi forgings. |

| YK20 | K20 | 14.3-14.6 | ≥86 | ≥2250 | Inokodzera inlaying rotary impact yekuchera matombo uye kuchera mune yakaoma uye yakaoma dombo maumbirwo. |

Order Process

Production Process

Packaging