I-Hard alloy ingxubevange ngokuyinhloko eyakhiwe yi-carbide eyodwa noma amaningana ephikisayo (njenge-tungsten carbide, i-titanium carbide, njll.) esesimweni sempushana, enezimpushana zensimbi (njenge-cobalt, nickel) esebenza njengesibophezelo. Ikhiqizwa ngenqubo ye-powder metallurgy. I-Hard alloy isetshenziselwa ikakhulukazi ukukhiqiza amathuluzi okusika anesivinini esikhulu namathuluzi okusika wezinto eziqinile neziqinile. Iphinde isetshenziswe ekukhiqizweni kwamafa abandayo asebenzayo, amageji anembayo, kanye nezingxenye ezingagugi kakhulu ezimelana nomthelela nokudlidliza.

▌ Izici ze-Hard Alloy

(1)Ukuqina okuphezulu, ukumelana nokugqoka, nobulukhuni obubomvu.

I-Hard alloy ibonisa ubulukhuni be-86-93 HRA ekamelweni lokushisa, elilingana no-69-81 HRC. Igcina ubulukhuni obuphezulu emazingeni okushisa angama-900-1000 ° C futhi inokumelana okuhle kakhulu nokugqoka. Uma kuqhathaniswa nensimbi yamathuluzi esivinini esikhulu, i-alloy eqinile inika amandla isivinini sokusika esiphindwe izikhathi ezingu-4-7 futhi sinesikhathi sokuphila esiyizikhathi ezingu-5-80 ubude. Ingakwazi ukusika izinto eziqinile ezinobunzima obufika ku-50HRC.

(2)Amandla aphezulu kanye ne-high elastic modulus.

I-Hard alloy inamandla acindezelayo aphezulu afika ku-6000 MPa kanye ne-elastic modulus esukela ku-(4-7) × 10^5 MPa, kokubili ephakeme kunaleyo yensimbi enesivinini esikhulu. Nokho, amandla ayo okuguquguquka aphansi kakhulu, ngokuvamile asukela ku-1000-3000 MPa.

(3)Ukumelana nokugqwala okuhle kakhulu nokumelana ne-oxidation.

I-Hard alloy ngokuvamile ikhombisa ukumelana okuhle nokugqwala komkhathi, ama-acids, ama-alkali, futhi ayithambekele kangako ekufakweni kwe-oxidation.

(4)I-coefficient ephansi yokunwetshwa komugqa.

I-Hard alloy igcina umumo nobukhulu obuzinzile phakathi nokusebenza ngenxa ye-coefficient yayo ephansi yokunwetshwa komugqa.

(5)Imikhiqizo enomumo ayidingi ukwenziwa kwemishini eyengeziwe noma ukugaywa kabusha.

Ngenxa yokuqina nokuqina kwayo okuphezulu, i-alloy eqinile ayiqhubeki nokusikwa noma ukugaywa kabusha ngemva kokwakhiwa kwe-powder metallurgy kanye ne-sintering. Uma kudingeka ukucubungula okwengeziwe, izindlela ezinjengomshini wokukhipha ugesi, ukusika izintambo, ukugaya nge-electrolytic, noma ukugaya okukhethekile ngamasondo okugaya kuyasetshenziswa. Ngokuvamile, imikhiqizo ye-alloy eqinile yobukhulu obuthile iyaqiniswa, iboshwe, noma iboshelwe emizimbeni yamathuluzi noma izisekelo zesikhunta ukuze zisetshenziswe.

▌ Izinhlobo Ezivamile Ze-Hard Alloy

Izinhlobo ze-hard alloy ezivamile zihlukaniswa ngezigaba ezintathu ngokusekelwe ekwakhiweni nezici zokusebenza: i-tungsten-cobalt, i-tungsten-titanium-cobalt, nama-tungsten-titanium-tantalum (niobium) alloys. Okusetshenziswa kakhulu ekukhiqizeni ama-tungsten-cobalt nama-tungsten-titanium-cobalt alloys aqinile.

(1)I-Tungsten-Cobalt Hard Alloy:

Izingxenye eziyinhloko yi-tungsten carbide (WC) ne-cobalt. Ibanga liboniswa ikhodi ethi "YG", elandelwa iphesenti lokuqukethwe kwe-cobalt. Isibonelo, i-YG6 ikhombisa i-tungsten-cobalt hard alloy enokuqukethwe kwe-cobalt okungu-6% nokuqukethwe kwe-tungsten carbide okungu-94%.

(2)I-Tungsten-Titanium-Cobalt Hard Alloy:

Izingxenye eziyinhloko yi-tungsten carbide (WC), i-titanium carbide (TiC), ne-cobalt. Ibanga liboniswa ikhodi ethi "YT", elandelwa iphesenti lokuqukethwe kwe-titanium carbide. Isibonelo, i-YT15 ikhombisa i-tungsten-titanium-cobalt hard alloy enokuqukethwe kwe-titanium carbide engu-15%.

(3)I-Hard Alloy ye-Tungsten-Titanium-Tantalum (Niobium):

Lolu hlobo lwe-hard alloy lwaziwa nangokuthi i-alloy hard universal noma i-alloy enzima ehlukahlukene. Izingxenye eziyinhloko yi-tungsten carbide (WC), i-titanium carbide (TiC), i-tantalum carbide (TaC), noma i-niobium carbide (NbC), ne-cobalt. Ibanga lichazwa ngekhodi ethi "YW" (osonhlamvukazi bethi "Ying" kanye "no-Wan," okusho ukuthi kanzima futhi jikelele ngesiShayina), kulandelwa inombolo.

▌ Izicelo ze-Hard Alloy

(1)Izinto Zethuluzi Lokusika:

Ingxubevange eqinile isetshenziswa kabanzi ekukhiqizeni izinto zamathuluzi okusika, okuhlanganisa amathuluzi okuguqula, abasiki bemishini yokugaya, ama-planer blades, ama-drill, njll. Ama-alloys aqinile e-Tungsten-cobalt afaneleka ekusetshenzisweni kwe-chip emfushane yezinsimbi ezinsimbi ezisansimbi nezingezona ayoni, njengensimbi ecijile, ithusi eliphonsiwe, nokhuni oluhlanganisiwe. Ama-alloys aqinile e-Tungsten-titanium-cobalt afanele ukwenziwa kwe-chip ende yensimbi nezinye izinsimbi. Phakathi kwama-alloys, lawo anokuqukethwe okuphezulu kwe-cobalt afaneleka umshini onzima, kanti lawo ane-cobalt ephansi afanele ukuqedwa. Ama-alloy aqinile ajwayelekile anempilo yamathuluzi ende kakhulu lapho kwenziwa izinto okunzima ukuzisika njengensimbi engagqwali.

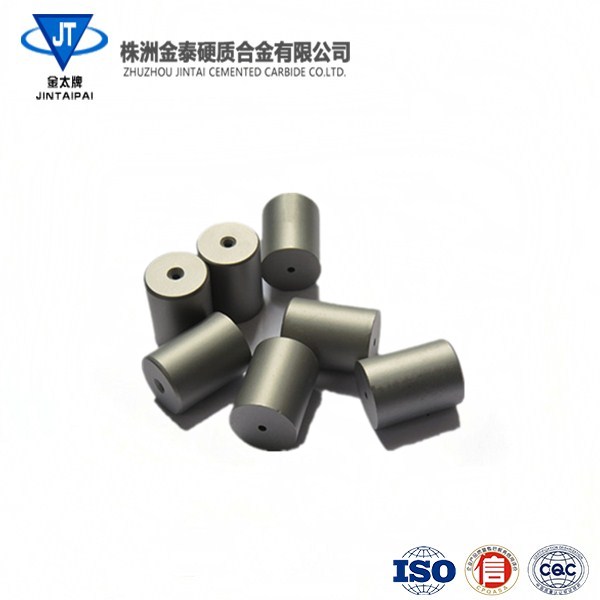

(2)Izinto zokukhunta:

I-Hard alloy ivame ukusetshenziswa njengempahla yokudweba okubandayo, ukufa kwesitembu esibandayo, ukufa kwe-cold extrusion, kanye nekhanda elibandayo liyafa.

I-Hard alloy cold heading die ingafakwa ngaphansi komthelela noma izimo zomthelela ezinamandla. Izici ezibalulekile ezidingekayo wukuqina okuhle komthelela, ukuqina kokuphuka, amandla okukhathala, amandla okugoba, nokumelana okuhle nokugqokwa. Ngokuvamile, okuqukethwe kwe-cobalt okuphakathi nendawo kuya phezulu kanye nama-alloys anezinhlamvu ezimaphakathi kuya kwamahhadla akhethiwe. Amabanga ajwayelekile afaka i-YG15C.

Ngokuvamile, kukhona ukuhwebelana phakathi kokumelana nokugqokwa kanye nokuqina ezintweni eziqinile ze-alloy. Ukuthuthukisa ukumelana nokugqoka kuzoholela ekwehleni kokuqina, kuyilapho ukuqinisa ukuqina kuzoholela ekunciphiseni.

Uma umkhiqizo okhethiwe kulula ukukhiqiza ukuqhekeka kusenesikhathi kanye nokulimala okusetshenziswayo, kufanelekile ukukhetha uhlobo olunokuqina okuphezulu; Uma umkhiqizo okhethiwe kulula ukukhiqiza ukugqoka kwangaphambi kwesikhathi kanye nokulimala okusetshenziswayo, kufanelekile ukukhetha uhlobo olunobulukhuni obuphezulu kanye nokumelana nokugqoka okungcono. Amabanga alandelayo: YG15C, YG18C, YG20C, YL60, YG22C, YG25C ukusuka kwesobunxele kuya kwesokudla, ubulukhuni buyancishiswa, ukumelana nokugqoka kuyancipha, ukuqina kuyathuthukiswa; Kunalokho, okuphambene kuyiqiniso.

(3) Amathuluzi okulinganisa nezingxenye ezingagugi

I-Tungsten carbide isetshenziselwa izinto ezifakwa ngaphakathi ezihuzukayo kanye nezingxenye zamathuluzi wokulinganisa, ama-bearings anemba emishini yokugaya, imihlahlandlela namabha aqondisayo emishini yokugaya engenamaphakathi, nezingxenye ezingagugi njengezikhungo ze-lathe.

Isikhathi sokuthumela: Aug-02-2023