Incazelo

I-Face Milling Cutter Ye-Aluminium Ingot

Ukubuka konke komkhiqizo:

I-aluminium ingot face milling cutter yakhelwe ukugaya ngaphezulu ngaphambi kokuginqika okushisayo

inqubo ye-aluminium ingots.I-aluminium material face milling cutter series ihlanganisa ama-rough

ama-milling cutter, ama-milling cutter anembayo, kanye nama-milling cutters

isetshenziselwa ukugaya ngobuningi bezikhala ezingenalutho.Isisiki sokugaya esinembayo sisetshenziselwa ukwenza ngcono

ubushelelezi obuphezulu be-aluminium ingots.I-milling cutter eboshiwe ithuthukisa ukumelana nokuguga kanye nokuphila kwama-blades.

Izici Zomkhiqizo:

1, Unqenqema lokugaya lubukhali, okuholela endaweni ebushelelezi ku-ingot ye-aluminium egayiwe, enhle.

ukucubungula ukuzinza.

I-2, i-blade inokuminyana okuphezulu nokuzinza, enikeza ukumelana nomthelela omuhle kakhulu nokumelana nokugqoka. 3, Indawo ye-blade inokushelela okuhle, iqinisekisa inqubo yokugaya enganamatheli futhi engashi.

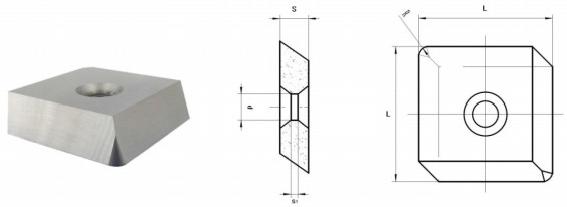

I-Rough Milling Cutter:

| Ikhodi ye-oda | Ubukhulu(mm | ||||

| L | R | d | S | s1 | |

| I-JT6206-L | 37.4 | 3 | 7 | 8 | 2 |

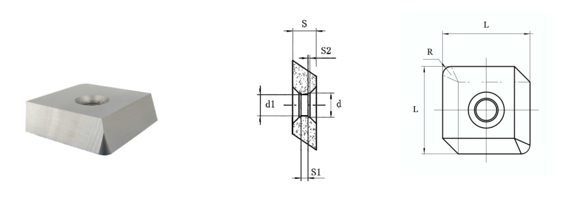

| Ikhodi ye-oda | Ubukhulu(mm) | ||||||

| L | R | S | S1 | S2 | d | d1 | |

| I-JT6206-M | 30 | 3 | 8 | 2.4 | 0.65 | 8.2 | 7.2 |

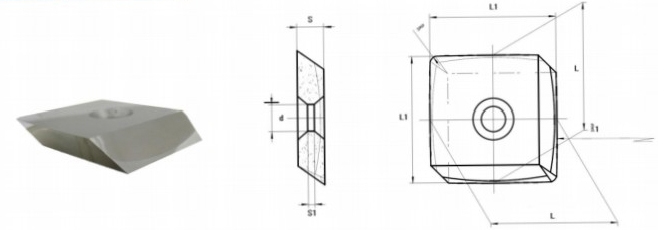

Qedela uMsiki Wokugaya:

| Ikhodi ye-oda | Ubukhulu(mm) | ||||||

| L | L1 | R | R1 | S | S1 | d | |

| I-JT6027 | 37.4 | 37.08 | 3 | 730 | 8 | 2 | 7.4 |

I-Coated Milling Cutter:

Uhlu Lwebanga

| Ibanga | Ikhodi ye-ISO | I-Physical Mechanical Properties (≥) | Isicelo | ||

| Ukuminyana g/cm3 | Ukuqina(HRA) | TRS N/mm2 | |||

| YG3X | K05 | 15.0-15.4 | ≥91.5 | ≥1180 | Ifanele ukwenziwa ngokunemba kwensimbi ekhonjiwe nezinsimbi ezingezona ayoni. |

| YG3 | K05 | 15.0-15.4 | ≥90.5 | ≥1180 | |

| YG6X | K10 | 14.8-15.1 | ≥91 | ≥1420 | Ifanele ukwenziwa kwemishini enembile kanye nokuqedwa kancane kwensimbi esakazwayo nezinsimbi ezingenayo ayoni, kanye nokucutshungulwa kwensimbi ye-manganese nensimbi ecishiwe. |

| YG6A | K10 | 14.7-15.1 | ≥91.5 | ≥1370 | |

| YG6 | K20 | 14.7-15.1 | ≥89.5 | ≥1520 | Ifanele ukuqedwa kancane kanye nomshini omahhadlahhadla wensimbi eyinsimbi nama-alloys alula, futhi ingasetshenziselwa umshini omahhadlahhadla wensimbi yokusansimbi kanye nensimbi ye-alloy ephansi. |

| YG8N | K20 | 14.5-14.9 | ≥89.5 | ≥1500 | |

| YG8 | K20 | 14.6-14.9 | ≥89 | ≥1670 | |

| YG8C | K30 | 14.5-14.9 | ≥88 | ≥1710 | Ifanele ukumba amatshe azungezayo kanye nezingcezu zokumba amatshe. |

| YG11C | K40 | 14.0-14.4 | ≥86.5 | ≥2060 | Ifanele izingcezu zamazinyo amise okweshizolo noma ayisiyingi emishinini yokumba amatshe esindayo ukuze ibhekane nokwakheka kwamadwala aqinile. |

| YG15 | K30 | 13.9-14.2 | ≥86.5 | ≥2020 | Ifanele ukuhlolwa okuqinile kwezinsimbi zensimbi namapayipi ensimbi ngaphansi kwezilinganiso zokucindezela okuphezulu. |

| YG20 | K30 | 13.4-13.8 | ≥85 | ≥2450 | Ifanele ukwenza isitembu siyafa. |

| YG20C | K40 | 13.4-13.8 | ≥82 | ≥2260 | Ifanele ukwenza isitembu esibandayo nokucindezela okubandayo kuyafa ezimbonini ezifana nezingxenye ezijwayelekile, ama-bearing, amathuluzi, njll. |

| YW1 | M10 | 12.7-13.5 | ≥91.5 | ≥1180 | Ifanele ukwenziwa kwemishini enembile kanye nokuqedwa kancane kwensimbi engagqwali kanye nensimbi evamile yealloy. |

| YW2 | M20 | 12.5-13.2 | ≥90.5 | ≥1350 | Ifanele ukuqedwa kancane kwensimbi engagqwali kanye nensimbi ye-alloy ephansi. |

| YS8 | M05 | 13.9-14.2 | ≥92.5 | ≥1620 | Ifanele ukwenziwa ngokunemba kwensimbi, ama-alloys asekelwe ku-nickel okushisa okuphezulu, nensimbi enamandla amakhulu. |

| YT5 | P30 | 12.5-13.2 | ≥89.5 | ≥1430 | Ifanele ukusika umsebenzi osindayo wensimbi ne-cast iron. |

| YT15 | P10 | 11.1-11.6 | ≥91 | ≥1180 | Ifanele ukwenziwa kwemishini enembile kanye nokuqedwa kancane kwensimbi nensimbi yokusansimbi. |

| YT14 | P20 | 11.2-11.8 | ≥90.5 | ≥1270 | Ifanele ukwenziwa kwemishini enembile kanye nokuqedwa kancane kwensimbi nensimbi esakazwayo, enesilinganiso sokuphakelayo esimaphakathi. I-YS25 yakhelwe ngokukhethekile ukusebenza kokugaya ensimbi nensimbi. |

| YC45 | I-P40/P50 | 12.5-12.9 | ≥90 | ≥2000 | Ifanele amathuluzi okusika umsebenzi osindayo, ohlinzeka ngemiphumela emihle kakhulu ekuguquleni ama-castings nama-forging ensimbi ahlukahlukene. |

| YK20 | K20 | 14.3-14.6 | ≥86 | ≥2250 | Ifanele inlaying izingcezu zokumba amatshe ajikelezayo kanye nokubhoboza amatshe aqinile futhi aqinile uma kuqhathaniswa. |

Inqubo yoku-oda

Inqubo Yokukhiqiza

Ukupakisha